We manufacture parts in a range of materials using high-precision technology to ensure quality and efficiency.

SET47 is a trusted partner for manufacturing machined components, serving industries including manufacturing, recreation, transportation, medical equipment, and high-tech. Our wealth of experience and our team’s expertise make us a valuable resource for conventional machining and CNC machining. Our machine shop can address all of your tooling needs, from prototype development to small-, medium-, and large-scale production, all the way through to CMM inspection to meet your industry’s most stringent quality standards. Thanks to our state-of-the-art equipment, we can guarantee efficient production and quick delivery for all of your machined parts.

Learn more about SET47 >

CNC Machining

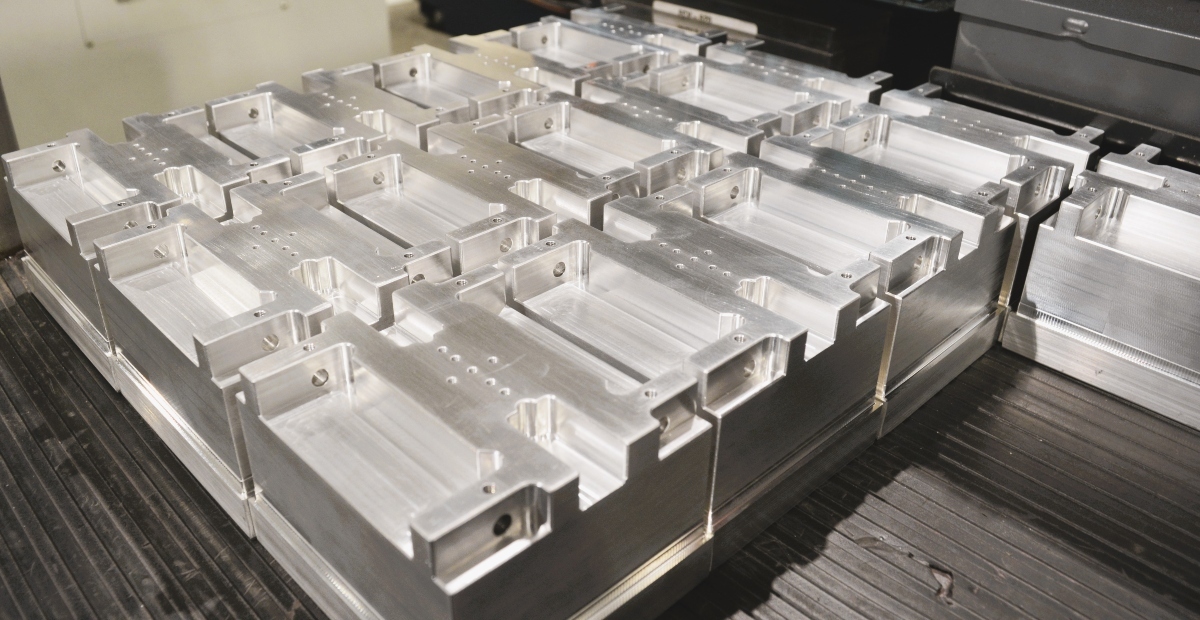

We have the flexibility you need. We are capable of meeting your outsourcing needs for CNC machined parts in small or large series (turning, 3-4-5 axis milling).

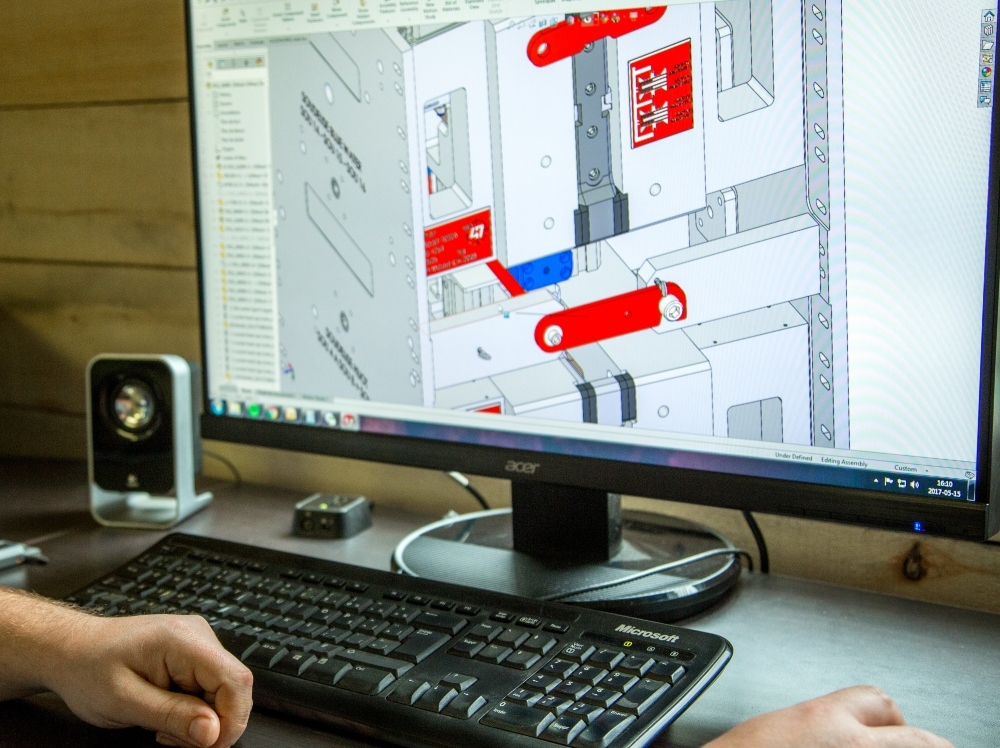

TOOL DESIGN

Specialized tools and jigs help enhance overall work methods’ efficiency. Looking for ideas to enhance your production? We have the ideas and expertise to bring them to life.

INSPECTION AND METROLOGY

The technology of three-dimensional measurement inspection at your service. Have your parts inspected right here. Your components will undergo a rigorous quality control measurement process using a 3D measuring machine (CMM).

High-precision, high-quality machining services

As experts in tool design and production, we are able to provide exceptional service for every request, whether it’s simple or incredibly complex. No matter the type of project at hand, from developing production tooling to entire machines, we will apply a rigorous approach that guarantees flawless results and sets your company up for success.

Advanced technologies for precision machining

Thanks to our state-of-the-art equipment, we can machine small, medium, and large components. Our machinery includes 3-4 and 5-axis machining centers, CNC lathes, and a range of conventional machining centers. To guarantee the precision and quality of our work, our team of experts uses a vast array of metrology and inspection equipment (CMM).

5 reasons to do business with SET47

Precision

Our cutting-edge machine shop is equipped with CNC machining technology capable of meeting the most demanding requirements with precision. We excel at manufacturing parts in all alloys, whether they’re simple or complex.

Methodology

When machining each component, we apply a rigorous methodology to ensure we follow all of the steps required to produce flawless results. That’s what we’re all about at SET47.

Expertise

With more than 15 years of experience in traditional machining and CNC machining, we apply our expertise to every step of your project – from ideation to prototyping, development, and manufacturing.

Quality

Our skilled team takes every last detail into account – nothing gets past them! What’s more, our CMM inspection equipment ensures the consistency and reliability of our work, allowing us to meet the highest possible standards.

Speed

We can bring your ideas to life with exceptional speed. We place a particular emphasis on our processes’ performance to meet delivery deadlines and efficiently respond to your requests.

Contact us for an estimate!

Serving a wide range of industries

SET47 specializes in precision machining for parts, tools, and equipment for transportation (namely cars and recreational vehicles), manufacturing, medical, and high-tech.